科学家利用3D打印技术开发新的超声设备

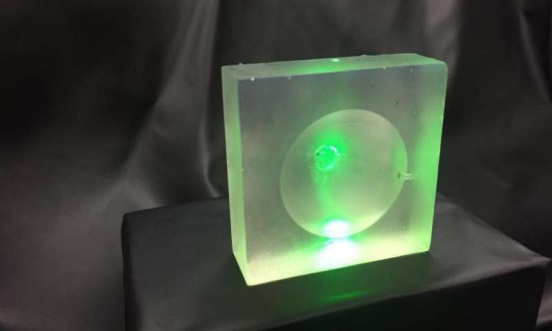

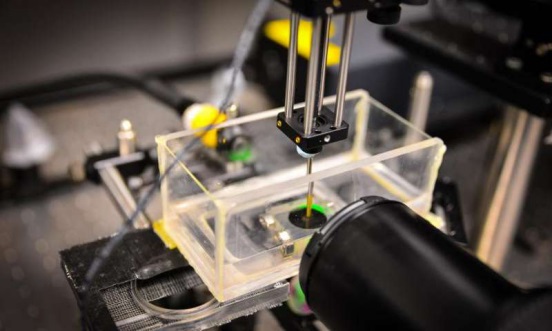

新加坡南洋理工大学的科学家们,通过3D打印镜头,已经开发出一种新的超声装置,其图像更加清晰。有了更清晰图像的辅助,医生们在进行非侵入式诊断和手术时,就能够提高可控度和精度。新的设备能够提供更精确的医疗程序,包括使用超声波杀死肿瘤,疏通血管,并将药物输送到靶细胞上。这种创新的超声波设备配备了卓越的树脂镜头,这个镜头是3D打印出来的。目前的超声波机器中,超声波镜头是圆柱形或球形的,这限制了成像的清晰度。利用3D打印,可以制造复杂的镜头形状,因此,可以产生更清晰的图像。3D打印镜头能够让超声波多点聚焦,或在病灶的位置聚焦,目前的超声仪器是无法做到的。

业界合作伙伴热衷于开发商业应用

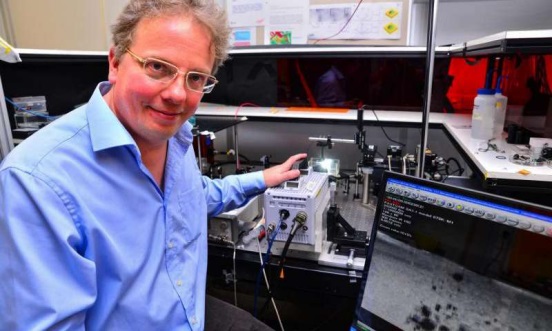

新型超声装置是由一个多学科的科学家团队开发的,该团队的领导者是南洋理工大学物理和数学学院的副教授克劳斯-迪特尔 奥尔。该超声设备经历了严格的测试,研究结果已发表在《应用物理快报》上,这是一家领先全球的科学研究所——美国物理研究所的同行评议期刊。有个这项突破,目前,南洋理工大学团队正在与业内合作伙伴进行商业谈判,出于医疗和研究应用的目的,他们都有意开发原型机。

副教授克劳斯-迪特尔 奥尔说:“在大多数医疗手术中,精度和非侵入式诊断方法都是至关重要的。这个创新设备不仅能够确定超声波的焦点,也能确定镜头的形状,提高医生手术的准确度和控制度。”

克服目前的局限

超声波的产生是通过在玻璃或“镜头”表面发射声波,以创造高频振动。

在传统的超声设备中,产生的热量会导致镜头迅速扩大,引发高频振动,产生超声波。用3D打印的镜头,新的超声设备能够克服玻璃的局限性。这种订制的、复杂的3D镜头可根据不同的目的来生产,不仅有更清晰的图像,而且更加便宜,易于生产。

“3D打印彻底变革了制造工艺,能够创造独特和复杂的设备。反过来,医疗设备的生产方式需要重新思考。这是科学界一个激动人心的发现,因为它给医学研究和医学手术开启了一扇新的大门。”副教授奥尔说。这项突破进入超声市场,到2020年这一市场预计将会增长到约69亿美元的规模。它也将促进新的医疗技术和健康科学的研究机会,如外科手术和生物技术。例如,研究人员能够利用声波来测量培养皿中细胞的弹性,了解它们对于外力会做出何种反应。对于区别良性和恶性肿瘤细胞也有用处。

“这是一项非常有前景的技术突破,对于医疗行业有重大益处,包括癌症成像领域。该技术能够降低图像失真,更加准确地将非癌软组织与癌症细胞区分开,” 助理教授Tan Cher Heng说,他是南洋理工大学李光前医学院解剖和放射学系主任,也是Tan Tock Seng医院放射诊断部高级顾问。(张微/编译)

以下为英文原文:

Scientists build new ultrasound device using 3-D printing technology

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a new ultrasound device that produces sharper images through 3-D printed lenses.

With clearer images, doctors and surgeons can have greater control and precision when performing non-invasive diagnostic procedures and medical surgeries.

The new device will allow for more accurate medical procedures that involve the use of ultrasound to kill tumours, loosen blood clots and deliver drugs into targeted cells.

This innovative ultrasound device is equipped with superior resin lenses that have been 3-D printed.

In current ultrasound machines, the lens which focuses the ultrasound waves are limited to cylindrical or spherical shapes, restricting the clarity of the imaging.

With 3-D printing, complex lens shapes can be made which results in sharper images. The 3-D printed lenses allow ultrasound waves to be focussed at multiple sites or shape the focus specially to a target, which current ultrasound machines are unable to do.

Industry partners keen to develop commercial applications

The novel ultrasound device was developed by a multidisciplinary team of scientists, led by Associate Professor Claus-Dieter Ohl from NTU's School of Physical and Mathematical Sciences.

The ultrasound device had undergone rigorous testing and the findings have been published in Applied Physics Letters, a peer-reviewed journal by a leading global scientific institute – the American Institute of Physics.

With this breakthrough, the NTU team is now in talks with various industry and healthcare partners who are looking at developing prototypes for medical and research applications.

Associate Professor Claus-Dieter Ohl said, "In most medical surgeries, precision and non-invasive diagnosis methods are crucial. This novel device not only determines the focus of the wave but also its shape, granting greater accuracy and control to medical practitioners."

Overcoming current limitations

Ultrasound waves are produced by firing sound waves at a glass Surface or 'lens' to create high-frequency vibrations.

In conventional ultrasound machines, the resulting heat causes the lens to expand rapidly, generating high frequency vibrations that produce ultrasound waves.

With lenses that are 3-D printed, the new ultrasound device overcomes the limitations of glass. Customised and complex 3-D printed lenses can be made for different targets which not only results in better imaging, but are cheaper and easier to produce.

"3-D printing reinvents the manufacturing process, enabling the creation of unique and complex devices. In turn, the way medical devices are created needs to be rethought. This is an exciting discovery for the scientific commUnity as it opens new doors for research and medical surgery," said Assoc Prof Ohl.

This breakthrough taps into an ultrasound market which is expected to grow to about US$ 6.9 billion by 2020. It is also expected to promote new medical techniques and research opportunities in health sciences such as surgery, and biotechnology.

For example, researchers could use the sound waves to measure elastic properties of cells in a petri dish, seeing how they respond to forces. This will be useful for example, to distinguish between harmful and benign tumour cells.

"This is a very promising breakthrough, potentially offering significant clinical benefits including to the field of cancer imaging. This technology has the potential to reduce image distortions and more accurately differentiate cancerous from non-cancerous soft tissue," said Adjunct Assistant Professor Tan Cher Heng, LKCMedicine Lead for Anatomy & Radiology and Senior Consultant with the Department of Diagnostic Radiology at Tan Tock Seng Hospital.